Fully automatic high-speed 2.0 air duct U-shaped line 5

Advanced manufacturing production line designed for efficient, large-scale production of ventilation ducts. Achieves automatic processing from coil feeding to finished duct forming

Category:

Duct Series

Key words:

Duct Series

Optional

+Intelligent production management system - MES management, complete the direct management of production equipment in the office , conduct unmanned production data transmission, complete data feedback and production process tracking

+Square reinforcement, add inner flange

+Stud snap bite

+Muffler production function

+ C shaped flange

+ Distal duct processing function(plug)

FEATURES

1. The production data input mode can be MES system LAN direct connection mode (optional) or manual input mode.

2. The right-angle edge is made by a locker forming machine, which is more straight and solves the matter that the right-angle edge is less than 90 degrees.”

3. Adopt the double mode of cylinder pushing down material and servo driving up material, optimize the structure and improve the speed.

4. With anti-slip mark structure design, effectively reduce bottom scratch.

5. Structural change improves daily production, and the minimum single chip speed is no more than 18 seconds.

6. Pneumatic pressure arm helps to prevent the loose material of plates above 1.2mm (optional).

7. The Pittsburgh locker is on the small side (front), which is convenient and labor-saving.”

FUNCTIONAL PROCESS

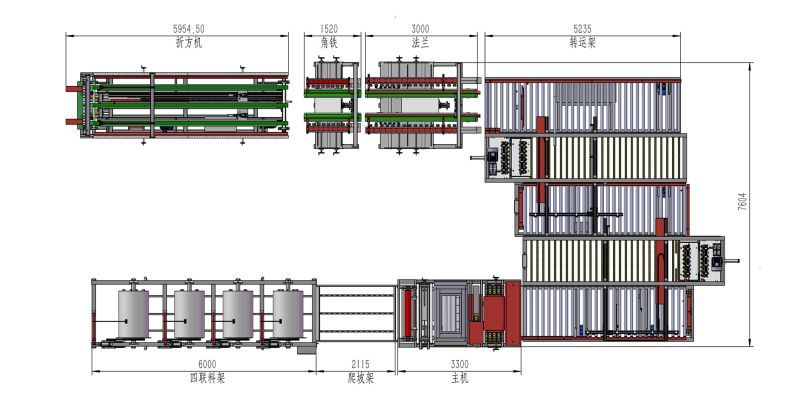

Uncoiling→ leveling → grooving → punching ports and holes → cutting to length → 1 # conveyor → 2 right-angle edge lifting locker forming machine → 2 # conveyor → 2 Pittsburgh locker forming machine → 3 # conveyor → double machine linkage angle bar flange machine, double machine linkage TDF flange machine → manipulator feeding conveying platform → folding square → discharging

TECHNICAL INDICATORS

1.0.5-2.0mm galvanized sheet, 0.5-1.5mm stainless steel(304) angle bar flange air duct;

0.5-1.5mm galvanized sheet,0.5-1.2mm stainless steel (304) TDF flange air duct.

2.Optional film covering function and welding mode.

3.Optional middle support hole and flange hole on both sides.

4.The daily processing capacity is 2000-4000 square meters.

BASIC CONFIGURATION

| 1. An electric integrated decoiler, include 4pcs of 7 tons coils (optional 8 tons or 10 tons of hydraulic decoiler) |

| 2.A supporting frame |

| 3.A host(leveling and grooving, punching ports and holes,cutting to length) |

| 4. 1 # conveyor |

| 5. Two T-type independent lifting right-angle edge locker forming machine |

| 6. 2 # conveyor |

| 7. Two T-type independent lifting Pittsburgh locker forming machine |

| 8. 3 # conveyor |

| 9. One double-machine linkage TDF flange machine |

| 10. One double-machine linkage angle bar flange machine |

| 11. One set of folding platform |

| 12. One set of control system |

WORK FLOW

MAIN TECHNICAL DATA

| NO. | Model | Capacity in mild-steel thicknessrange (mm) | Max-width (standard) (mm) | Max-working speed (m/min) | Coiler max-weight (kg) | Dimensions(mm) | Power (kw) | Weight (kg) | ||

| L (mm) | W (mm) | H (mm) | ||||||||

| 1001-1 | ADL-U5K-1500-Z-S | Stainless steel0.5-1.5 galvanized sheet0.5-2.0 | 1500 | 15 | 7000 | 20000 | 8200 | 1500 | 44 | 21000 |

| 1001-2 | ADL-U5K-1250-Z-S | Stainless steel0.5-1.5 galvanized sheet0.5-2.0 | 1250 | 15 | 7000 | 20000 | 7500 | 1500 | 42 | 21000 |

FACTORY

SHANDONG ANSHECL MACHINERY CO.,LTD is a company specialized in the design, production, and sales of automated production lines. The company has a production workshop of 10,000 square meters and is engaged in the research, development, production, and sales of laser production lines, optical products, and high-temperature new materials.

Exhibition

The company is committed to promoting the development of the environmental protection industry through technological innovation. The company has a comprehensive quality management system and has obtained IS09001 quality system certification and EU CE quality system certification.

RELATED PRODUCTS

MESSAGE