Semi hobbing laser cutting

A more efficient option - coil laser cutting machine, automatic feeding, continuous production. Save time, labor and cost.

Category:

Rolling laser

Key words:

Rolling laser

Gear hobbing platform laser cutting machine

Intelligent production management system - MES management, complete the office,s direct management of production equipment, conduct unmanned production data transmission, complete data feedback, and production process tracking (optional).Effectively reduce scratches.

High grade aviation aluminum material is used, with a rigidity increase of 60%, high temperature resistance, and improved equipment operation stability. Aviation aluminum is light in weight, with a total weight reduction of 20%, which meets the needs of high-speed and high-precision operation of the beam and is not prone to deformation. The 10000 ton extrusion production and processing process ensures excellent mechanical properties of the beam and reduces the failure rate.

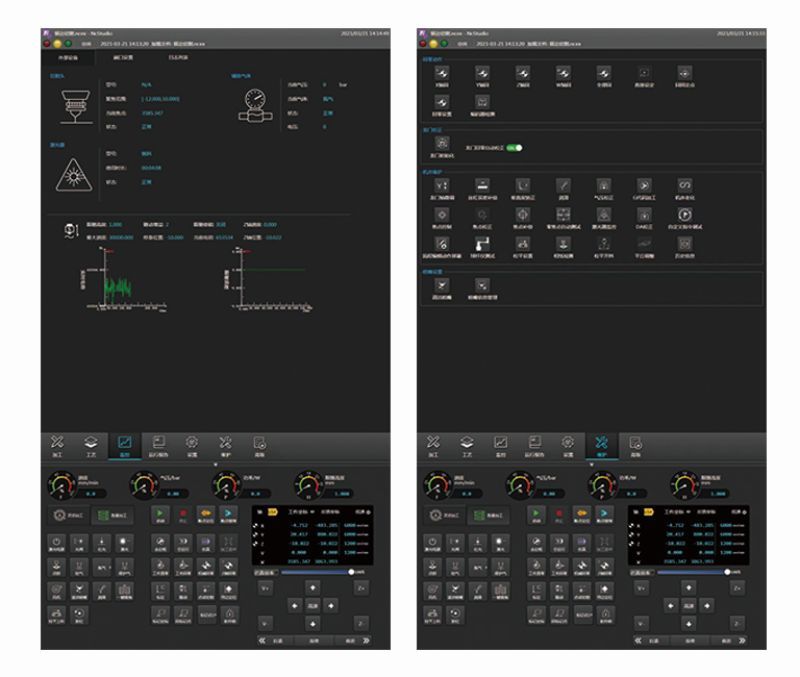

CONTROL SYSTEM

Good openness, supporting multiple file formats such as G code (NC), DXF, PLT, ENG, and so on; Support a variety of pulse modulated signals, which can be matched with different lasers and cutting speeds to adjust the duty ratio, improving the quality of perforation; The imported graphics can be preprocessed.

FUNCTION

Uncoiling - leveling - cutting - sorting - marking (optional)

SUPERIORITY

Control costs from the source, reduce secondary handling, improve efficiency and save labor.

BASIC CONFIGURATION

| 1. One set of material rack |

| 2. One set of leveling machine |

| 3. One set of laser cutting host |

| 4. One set of material receiving platform |

| 5. One set of identification system (optional) |

| 6. A set of CNC control system |

| 7. One set of water cooler |

| 8. One set of voltage stabilizer |

SERIES PRODUCTS

| Model | Processing breadth | Whole machine weight | L×W×H mm |

| ZPL-4515-1500W | 4500X1500 | ≈10000 | 22000X3000X2000 |

FACTORY

SHANDONG ANSHECL MACHINERY CO.,LTD is a company specialized in the design, production, and sales of automated production lines. The company has a production workshop of 10,000 square meters and is engaged in the research, development, production, and sales of laser production lines, optical products, and high-temperature new materials.

Exhibition

The company is committed to promoting the development of the environmental protection industry through technological innovation. The company has a comprehensive quality management system and has obtained IS09001 quality system certification and EU CE quality system certification.

RELATED PRODUCTS

MESSAGE